UltraFlush Lube Oil Flush

The failure of one or more key components or the presence of carbon and/or varnish build-up can severely compromise equipment reliability, especially with large, complex equipment like stationary engines, turbines, paper machines, and plastic injection molders. When this happens, the associated lube system may require flushing and filtration to meet specified cleanliness levels.

Your ESI engineer may recommend this Integrated Lubrication Service (ILS) on the basis of an equipment inspection. This service offers a high velocity oil flush of the lubricant circulation system.

Application

ESI engineers work with plant personnel to:

- Identify critical production equipment and implement objectives that help ensure optimal performance

- Develop circulation system cleanliness specifications in conjunction with equipment builder and filtration supplier

- Coordinate arrangements with the ILS provider who will arrive on-site to: 1. Complete the high velocity flushing of circulation piping and related elements (see Process Details, reverse side), and 2. Gather key baseline and other relevant data for inclusion in the report

Potential Benefits

Potential benefits could include the following:

- Revenue improvement through reduction of unscheduled downtime

- Reduction in parts replacement and lubricant expenses

- Lower maintenance labor costs

- Improved equipment reliability and more effective maintenance control

- Reduced used lubricant disposal costs

Deliverable

Prepare an Engineering Service Report that:

- Details the lubricant treatment steps completed

- Documents the lubricant cleanliness level prior to and after treatment

- Recommends steps to maintain lubricant system cleanliness such as routine Oil System Preventive Maintenance

- Provides an estimated value of the service to the customer

Distribute and present the completed report to plant management and key personnel

Process Details

- Determine Flushing Protocol

- Select Proper Flush Oil

- Determine Whether System Cleaners are Required

- Set-up Equipment and Complete Flush

- Install Jumpers

- Set-up Flush Rig

- Document Test Results

- Take Photos and Complete Contaminant Analysis (Particle Count, Filter Patch)

- Inspect Filters from Flush Rig

- Complete Service Summary

Common Opportunity Areas

- Restricted oficaces leading to reduced flow rate

- Varnish/sludge buildup

- ISO Cleanliness outside of OEM specifications

- Repetitive component failures attributed to lubricant contamination

Safety, Health and Environment

ESI engineers:

- Are attuned to the hazards of handling, storage, and use of petroleum products

- Coordinate efforts through designated plant personnel

- Strictly observe the site's safety and environmental rules and ESI's safety practices

- Verify equipment electrical and mechanical lockout, proper tagging an potential explosion hazards prior to working on equipment

- Provide recommendations to reduce the hazards associated with spill, leakage and fire.

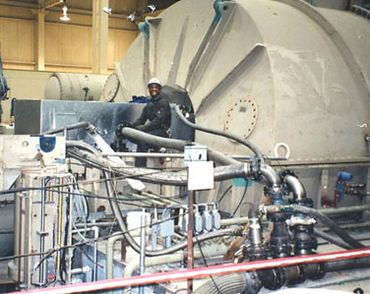

High velocity lube oil flushing. ESI provides the right pumps for the right system. ESI pumping equipment provides turbulent flows that transport all foreign particles from the system to a specially ESI designed 1 micron full flow filtration unit. ESI will monitor this quick flushing progress, with its electronic particle counters.

Clients who use UltraFlush get fast results, that meet the high cleanliness requirements, get a clean system and clean lube oil. ESI clients do not waste money and time with flushing oils.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.